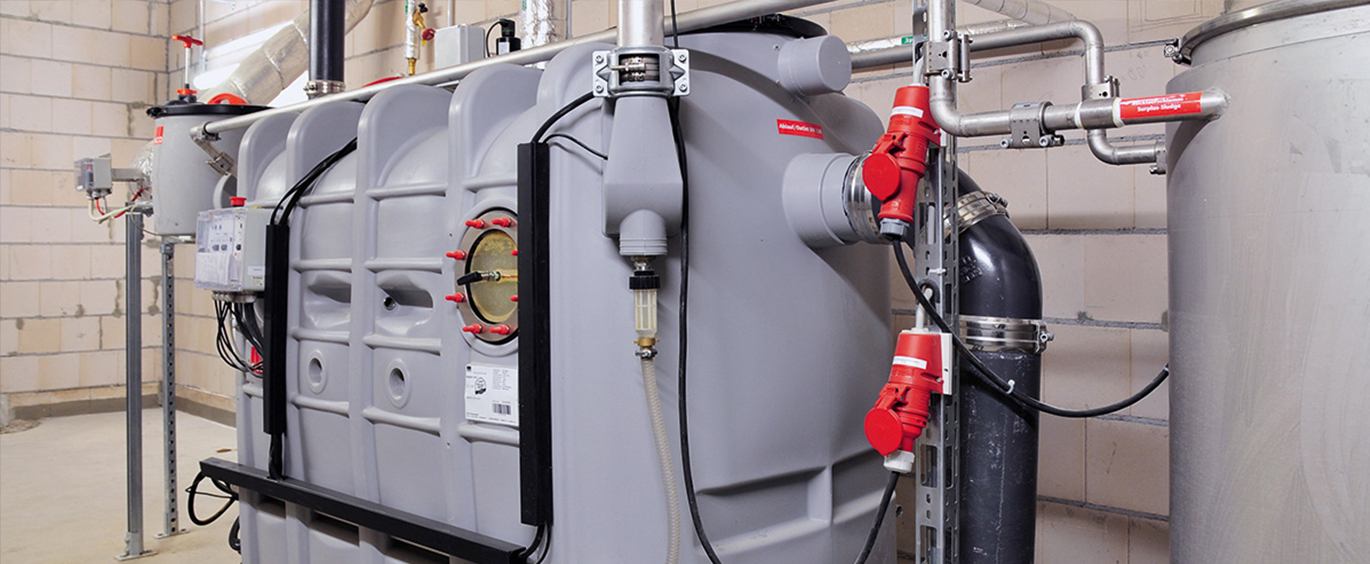

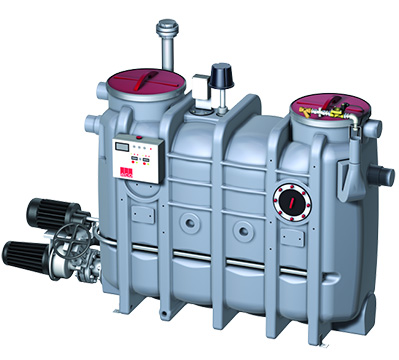

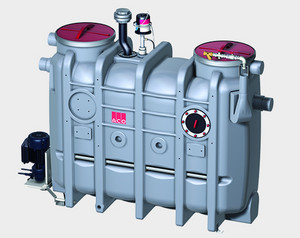

In restaurants, commercial kitchens and meat processing plants, grease in wastewater can accumulate. This kind of greasy wastewater is quite different from domestic wastewater, causing risks to pipelines and sanitary drainage objects. Greases and oils deposit on the walls of the pipes together with other wastewater constituents and can lead to corrosion, blockages and odour nuisance. For these reasons, the use of grease separators is mandatory in industrial and commercial environments where grease-polluted wastewater is produced.

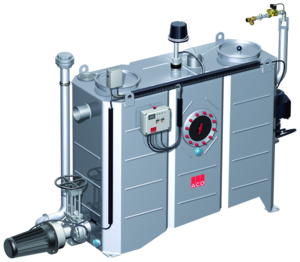

A grease separator works purely physically, applying gravity (difference in density), i.e. heavy wastewater contents sink to the bottom and light substances such as animal oils and fats rise to the top of the separator. The treated wastewater is then discharged into the sewers via the drainage outlet pipe.

With grease separators for full disposal, sludge and grease collected in the separator container must be picked up by a disposal contractor at certain intervals or as required, and then treated collectively.